End Suction Norm Pumps

DanPumps S-ELP (DN 150 - DN 250 mm)

Product Applications

The DanPumps S-ELP pump, constructed to EN 1092 standards, is designed for clean or slightly contaminated low viscosity liquids without solid and fibrous particles.

Technical data

| Discharge Flange | DN 150 - DN 250 mm |

| Capacity | up to 1500 m³/h |

| Head | up to 100 m |

| Speed | up to 1500 rpm |

| Design Temperature | -10° C to +140° C* |

| Casing Pressure (Pmax**) | 10 bar (16 bar)* |

* The Material of pumps dier according to the type of pumped liquid, operating temperature and pressure. Contact for detailed information.

** Pmax: Suction Pressure + Shutoff Head

Industries

Design Features:

- Horizontal, radially split volute casing type, single stage, end suction centrifugal pump with closed impeller.

- Suction and discharge flanges conform to EN 1092-2/PN 16.

(EN 1092-1/PN 16 for steel or stainless steel casing) - Due to the back-pull-out design, the complete bearing assembly including impeller and casing cover can be dismantled without removing the volute casing from the pipe system. (With spacer coupling application, also possible to take out the rotor group without dismantling the electric motor).

- All impellers are balanced dynamically or statically according to ISO 1940 class 6.3.

- Axial thrust is balanced by impeller balancing holes system.

- Direction of rotation is clockwise viewed from drive end.

- Bearings of S-ELP type pumps are normally “life time grease lubricated” ball bearings, except S-ELP 200-500 and S-ELP 250-500 pumps, which are always oil lubricated.

Shaft Sealing

- The standard shaft seal is a mechanical Carbon/Silicon carbide with EPDM.

- Different seal variants are available depending on customer requests and liquid types.

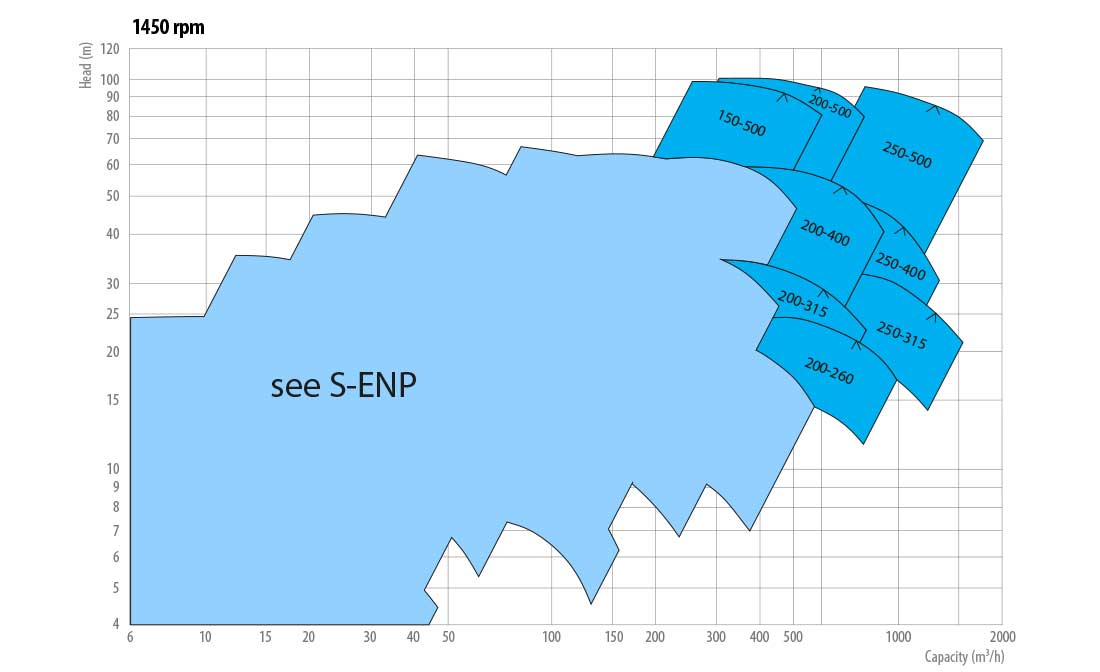

Performance Curves - Complete DanPumps S-ELP

Similar pumps:

DanPumps S-ENP

End Suction Norm Pumps

DanPumps S-ECP

End Suction Closed Coupled Pumps

DanPumps S-EMP

End Suction Multistage Pumps

DanPumps S-DSP

Double Suction Pumps

Dansk

Dansk English

English Australia

Australia Deutsch

Deutsch