End Suction Multistage Pumps

DanPumps S-EMP (DN 40 - DN 150 mm)

Product Applications

The DanPumps S-EMP pump is designed for clean or slightly contaminated low viscosity liquids without solid and fibrous particles.

Technical data

| Discharge Flange | DN 40 - DN 150 mm |

| Capacity | up to 400 m³/h |

| Head | up to 450 m |

| Speed | up to 3000 rpm |

| Design Temperature | -10° C to +140° C* |

| Casing Pressure (Pmax**) | 30 bar (63 bar)* |

* The Material of pumps dier according to the type of pumped liquid, operating temperature and pressure. Contact for detailed information.

** Pmax: Suction Pressure + Shutoff Head

Industries

Design Features:

- Horizontal ring section, multistage, centrifugal pumps with closed impellers and diffusers in end suction design.

- 7 Models from DN 40 up to DN 150 discharge flange diameter.

- Suction nozzle flanges conform to EN 1092 - 2/PN 16 and discharge nozzle flanges conform to EN 1092 - 2/PN 40 (PN 63) (For steel or stainless steel casing pumps, flanges conform to related pressure class ratings defined in EN 1092 - 1).

- Discharge flange is on top for standard production, upon request different discharge flange positions can be applied.

- All impellers are balanced dynamically or statically according to ISO 1940 class 6.3.

- Axial thrust is balanced by impeller balancing holes system.

- Direction of rotation is always counter clockwise viewed from drive end. That is why these pumps can not be accouppled directly with diesel engines.

- Bearings of S-EMP type pumps are grease lubricated.

- Journal bearing used in the suction side is lubricated by the pumping liquid.

Shaft Sealing

- The standard shaft seal is a mechanical Carbon/Silicon carbide with EPDM.

- Different seal variants are available depending on customer requests and liquid types.

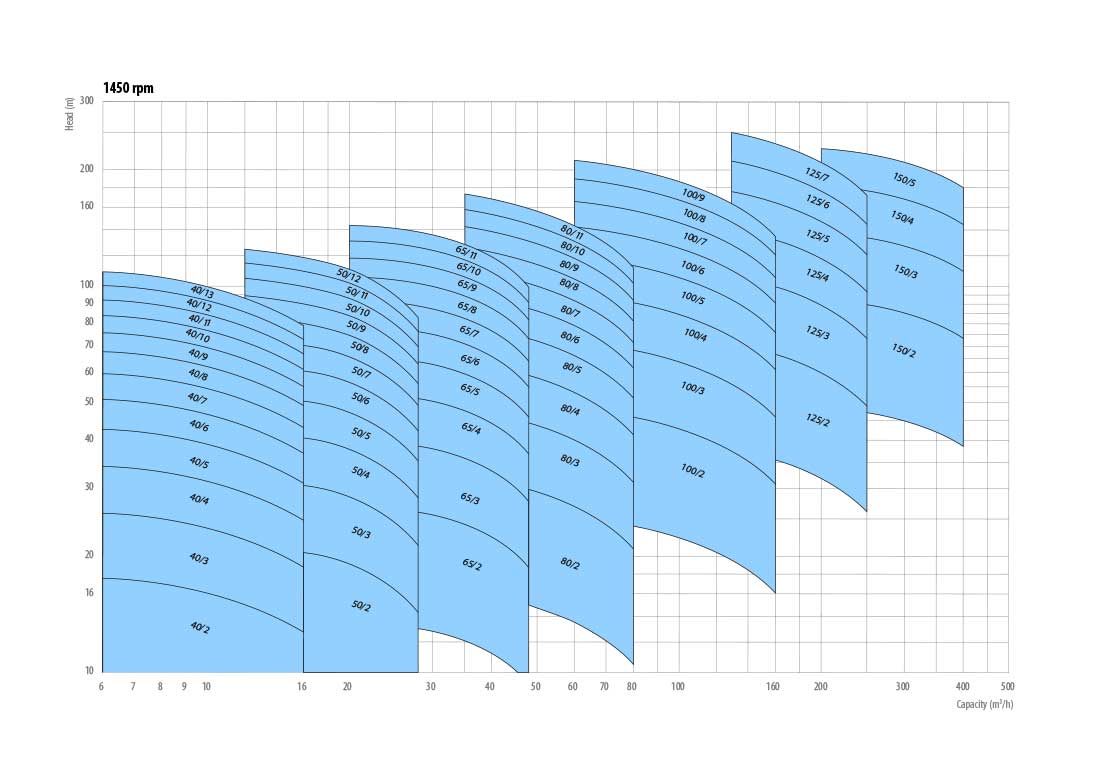

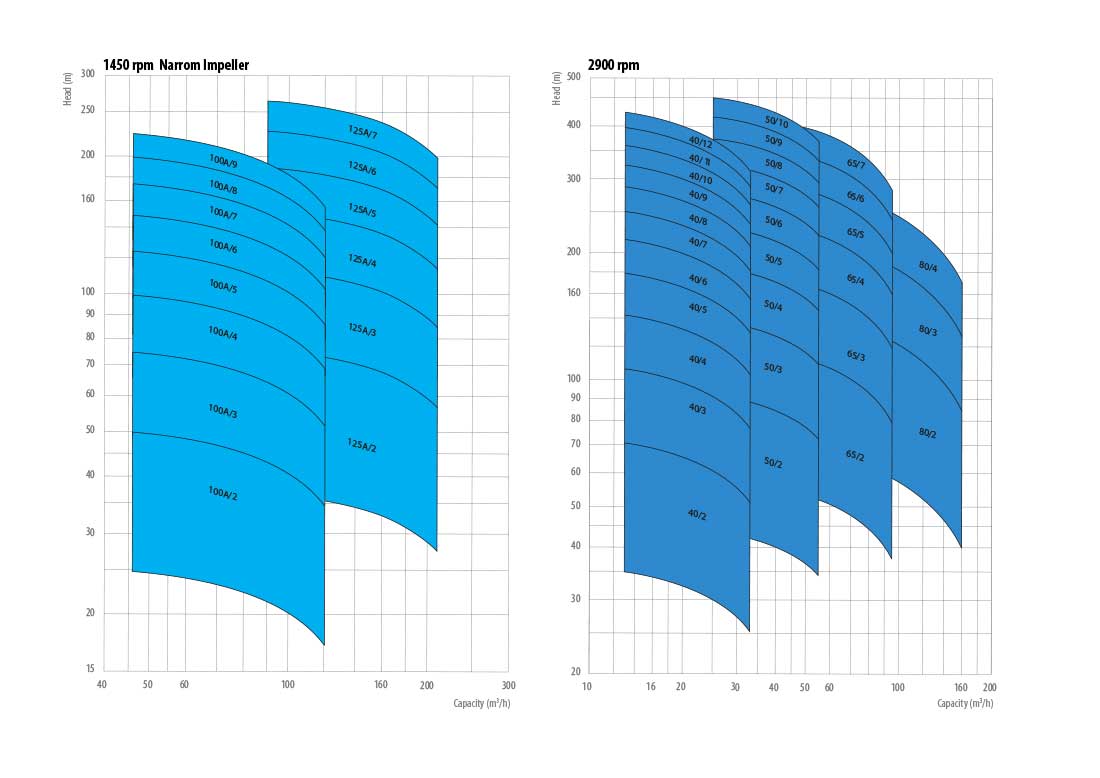

Performance Curves - Complete DanPumps S-EMP

Similar pumps:

DanPumps S-ENP

End Suction Norm Pumps

DanPumps S-ELP

End Suction Norm Pumps

DanPumps S-ECP

End Suction Closed Coupled Pumps

DanPumps S-DSP

Double Suction Pumps

Dansk

Dansk English

English Australia

Australia Deutsch

Deutsch