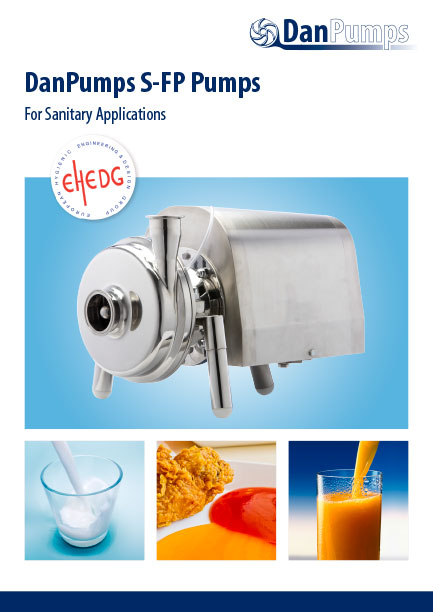

Sanitary S-FP pump

DanPumps sanitary S-FP pumps are designed for sanitary productions in the food, beverage, pharmaceutical and cosmetic industries. The pumps ensure gentle treatment of the delicate and temperature-sensitive media, with a flow rate of up to 100 m³/h.

Our sanitary pumps are EHEDG approved and comply with the strict requirements for cleaning and hygiene. The pump’s stainless steel surface has a roughness of less than 0,8 Ra.

Features:

- Operational reliability and low noise level

- Low NPSH guarantees good suction capacity

- Great energy efficiency

- Minimum of downtime

- Supporting leg designed to grant support during operation and maintenance

- EHEDG Certification

- CIP: Cleaning In Place

- Balanced impellers

- Easy switch from single to double mechanical seal

- O-rings

- Temperatures between -20°C and +140°C

- Capable of complete emptying

EHEDG: Hygienic design of sanitary pumps

All of our sanitary pumps are EHEDG-certified.

An EHEDG certification ensures that the product has been through an approval process and passed the requirements for cleaning and hygiene.

Cleaning

The sanitary pumps are designed for food and beverage processing and other sterile processes that require regular cleaning. The pump is easily cleaned with CIP-cleaning (Cleaning In Place) - The equipment, tanks, pipes, and process plants can be cleaned efficiently without disassembly, which saves time and money.

Hygiene

The pump’s surface is smooth with a roughness of less than 0.8 Ra and meets the expectations of the requirements for hygiene within the sanitary industry etc.

Maintenance

The S-FP pump is constructed for simple service and maintenance without special tools.

One of the focus points for DanPump's S-FP series is easy maintenance. The sanitary pump is designed for quick and easy service and maintenance without special tools.

DanPumps S-FP sanitary pumps can be used in the processing of many products:

- DAIRY PRODUCTS:

Unpasteurised milk, whey, cream, skimmed milk, concentrated milk, concentrated whey - FOODSTUFFS:

Egg products, vinegar, animal and vegetable oils and fats - NON-ALCOHOLIC BEVERAGES:

Syrups, fruits juice, concentrates, must - ALCOHOLIC BEVERAGES:

Liqueurs, wine, sparkling wine, beer - SUGARY PRODUCTS:

Liquid sugar, treacle, starch solution, glucose - BIOTECHNOLOGY:

Cellular suspensions, enzymes, nutrients solutions - BREWING:

Malt and water mixing, malt must, yeast - CHEMICALS:

Solvents, detergents, basic solutions, alkaline solutions, acid solutions - PHARMACEUTICAL/COSMETICS:

Infusion solutions, lotions, plant extracts, perfumes

Industries

Specifications

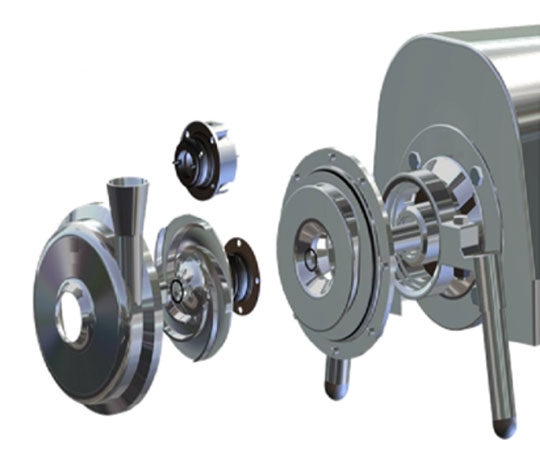

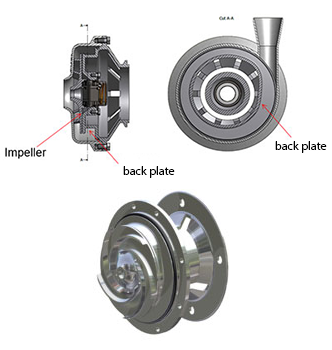

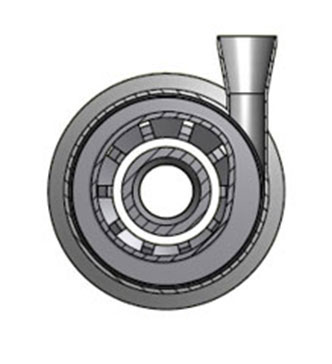

Semi-open impeller

This electro-polished stainless steel impeller is suitable for both low-viscosity and particle-containing pumped liquids.

- All DanPumps pumps are balanced and optimized according to the customer’s duty point.

- The impeller is easy to clean, and bacteria contamination is avoided.

- An impeller optimization is carried out to improve the efficiency and performance of the centrifugal pump.

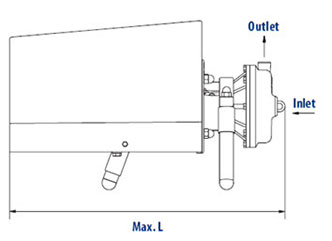

Volute casing

The unique design of the pump ensures that the outlet can be freely mounted 360° in all directions, which makes it easy to fit into any installation.

- Adjustable outlet 360º.

- Fully drainable.

Backplate & impeller

The impeller and the backplate are designed for optimal performance and high efficiency. The unique design of the backplate, placed behind the impeller, ensures a gentle process of the medium being pumped.

- The placement of the backplate ensures a steadier process and a continuous speed of the media being pumped.

- The power from the impeller does not affect the volute.

- Low NPSH guarantees good suction capacity.

- Low noise level.

Mechanical seal

The cartridge seal can be a single or double mechanical seal. The double mechanical seal is designed as a flushed seal, which acts as a lubricant to prevent the liquid from crystallizing.

Single mechanical seal: water, beer, milk, and other non-sticky liquids.

Double mechanical seal: sugar, syrup, and other sticky liquids.

- A user-friendly cartridge seal makes it possible to replace the seal without using any special tools or personnel with specific skills, which eliminates any risk of improper installation.

- Our pumps share the same mechanical shaft seal to simplify the spare parts inventory - together with easy service it reduces the maintenance costs.

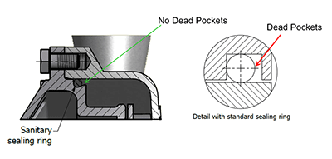

CIP (Cleaning in Place)

The sanitary pumps are designed for food and beverage processing and other sterile processes that require regular cleaning. Clean the pumps efficiently without disassembly.

- The pump has no dead pockets and can be considered sanitary.

- The pump is electropolished to ensure that no residues stick to the inside.

The conical jacket

Inner and outer walls are polished to meet the level of dairy hygiene standards.

- The fully welded jacket ensures a tight and long-lasting pump.

- The conical jacket design ensures that all water will run off the pump after cleaning.

High-efficiency Motor

DanPumps sanitary pumps are delivered with an electric motor manufactured according to international standards regarding IEC 60034-30 and fulfil the requirements of the EC Directive 2009/125 (eco-design for energy-related products).

- The shaft and backplate design make it easy to replace the norm. motor into a bigger or smaller version, if the pump duty needs to be changed. DanPumps S-FP pump is one of the most flexible pumps on the market.

O-rings

Choose between these rubber types:

- EPDM - max. heat 130 °C

Durability: 5-10 years - Viton - max. heat 210 °C

Durability: up to 20 years

- EPDM: Synthetic rubber – good for hot water and brake fluids (based on glycol).

- Viton: Fluorocarbon – excellent resistance to high temperatures and a broad range of chemicals.

Supporting leg

Designed to stabilize the pump during operation and service.

- The legs of the pump are fully adjustable, providing the pump with maximum flexibility.

- The surface roughness is also less than 1 Ra, ensuring the legs are suitable for sanitary pumps.

Low noise level

The pump presents a low noise level and gentle product processing.

- Measurements have been carried out in accordance with ISO 3743, Grade 2 and ISO 3746, Grade 3. Tolerance: ±3 dB.

Dansk

Dansk English

English Australia

Australia Deutsch

Deutsch